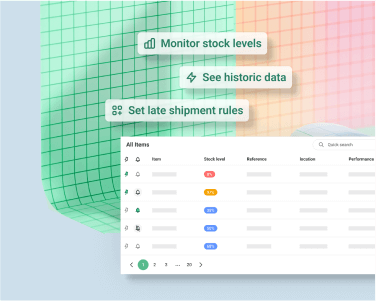

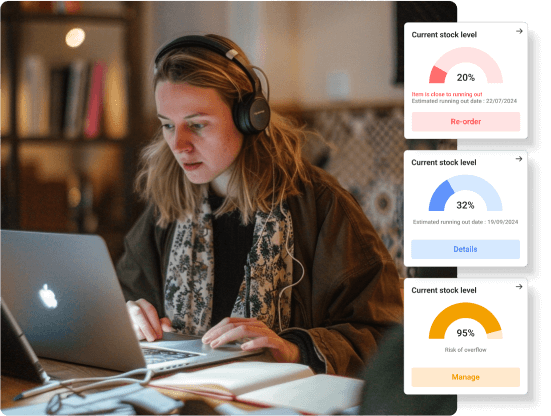

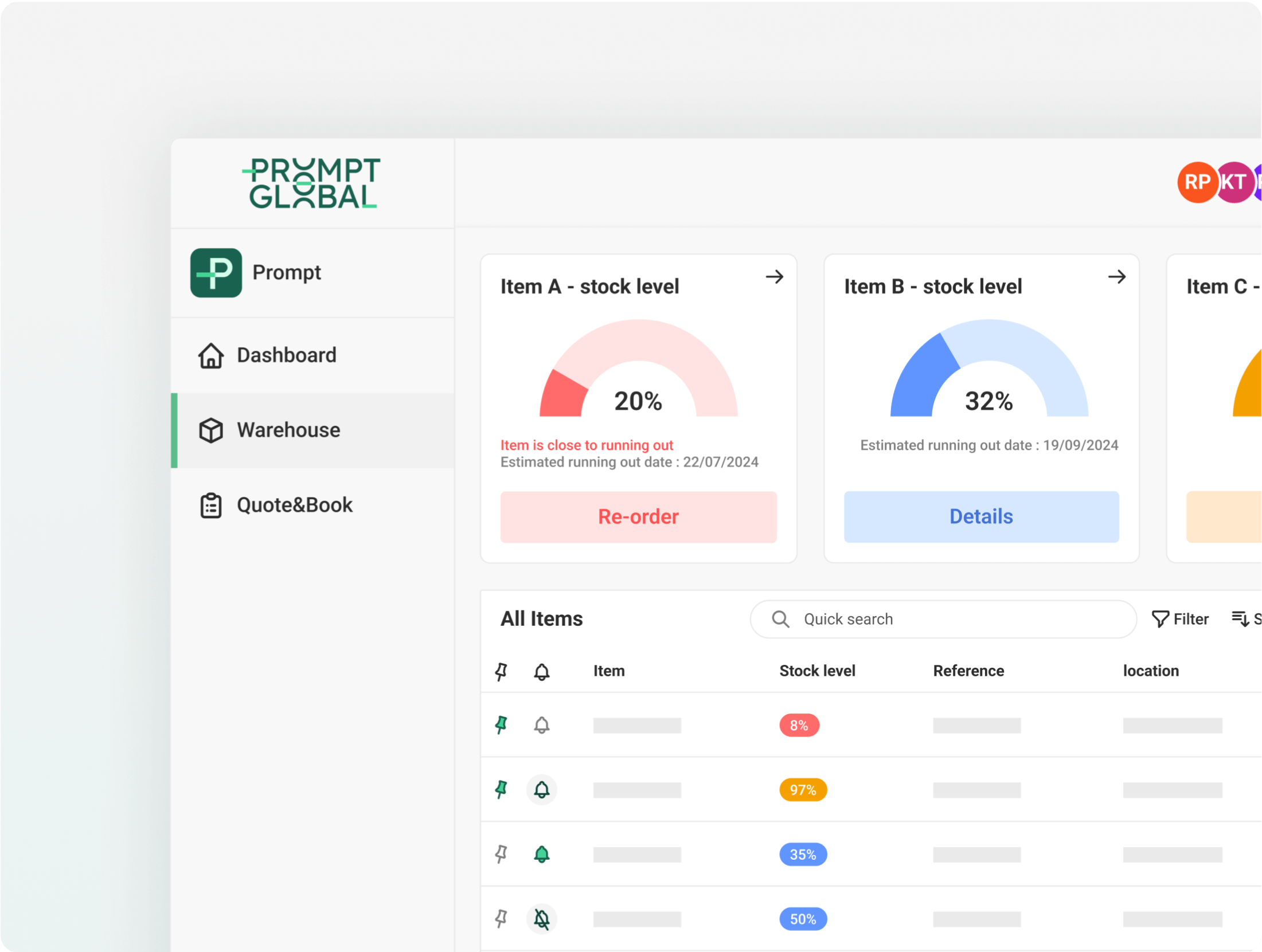

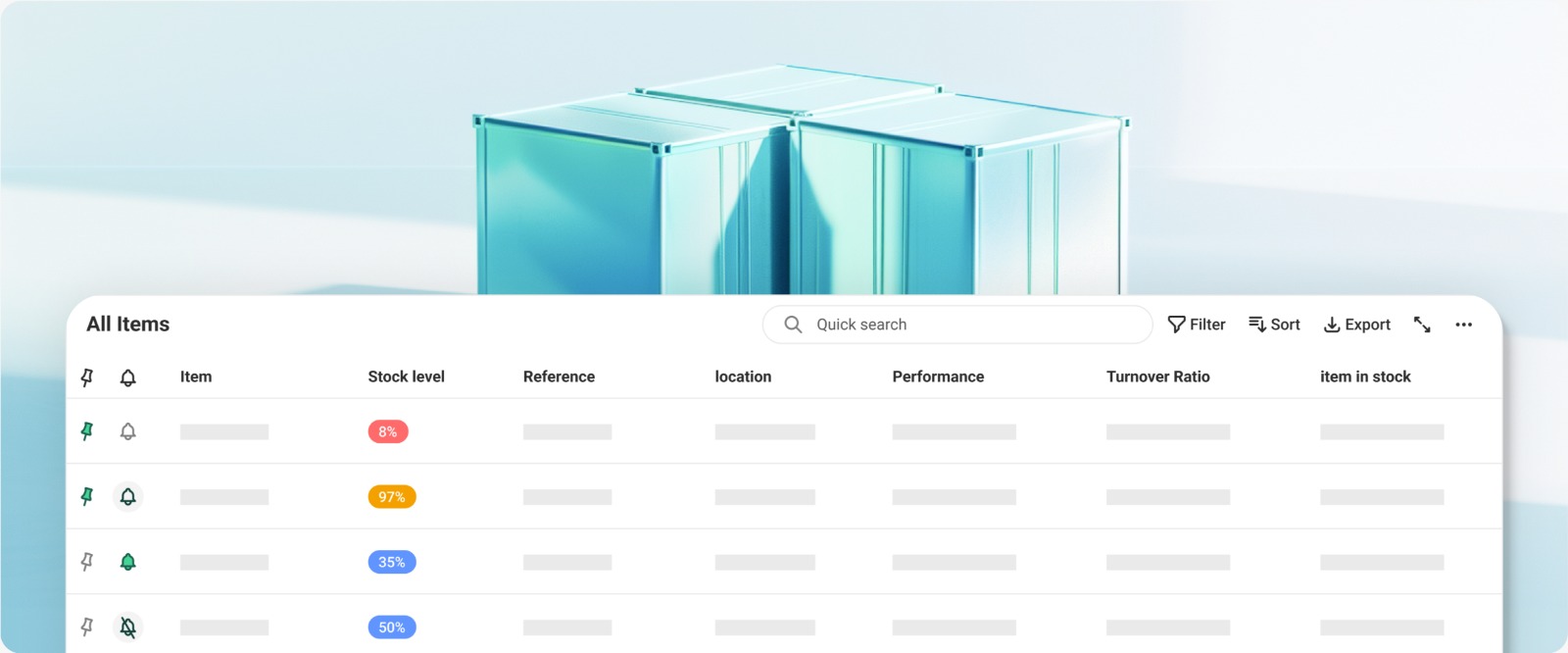

By connecting all your transport data, you can use current insights such as lead-times and macro events, as well as historic data for seasonal impact, to optimize your safety stock and always be well prepared.

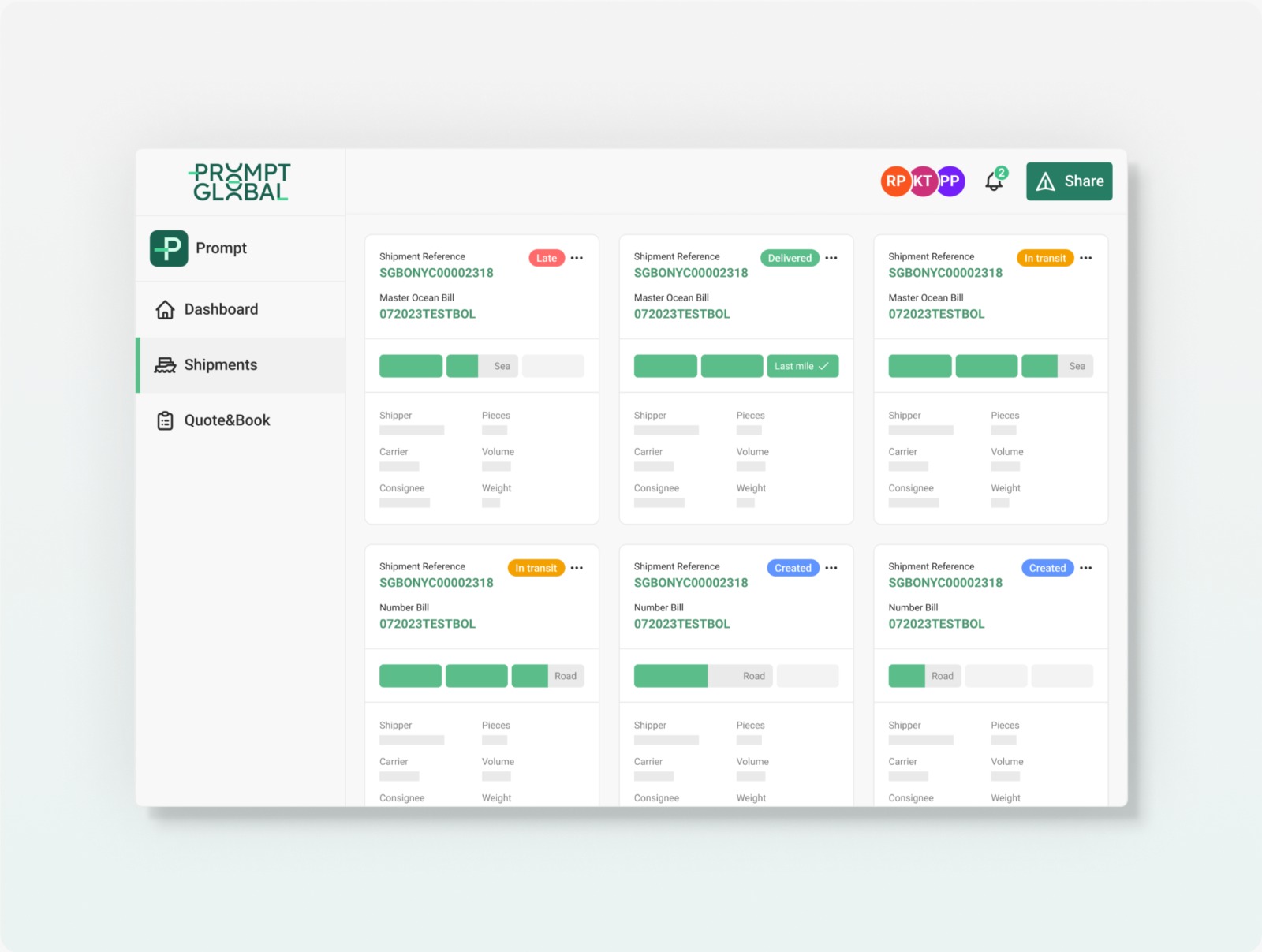

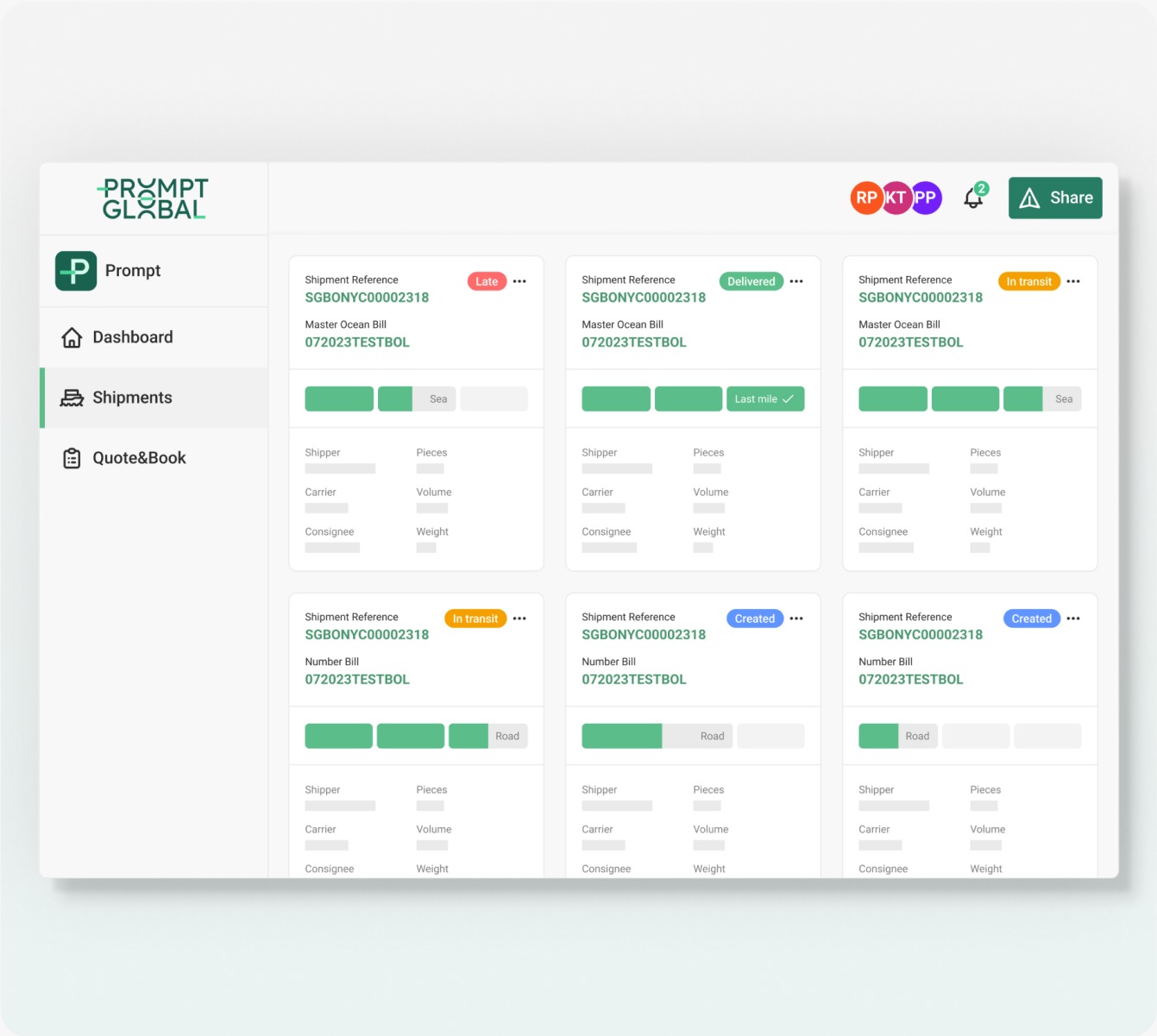

How your carriers perform will impact your supply chain management. Use real data such as transit times and past performance to identify recurring issues or potential failings, allowing you to better allocate capacity to top performers.

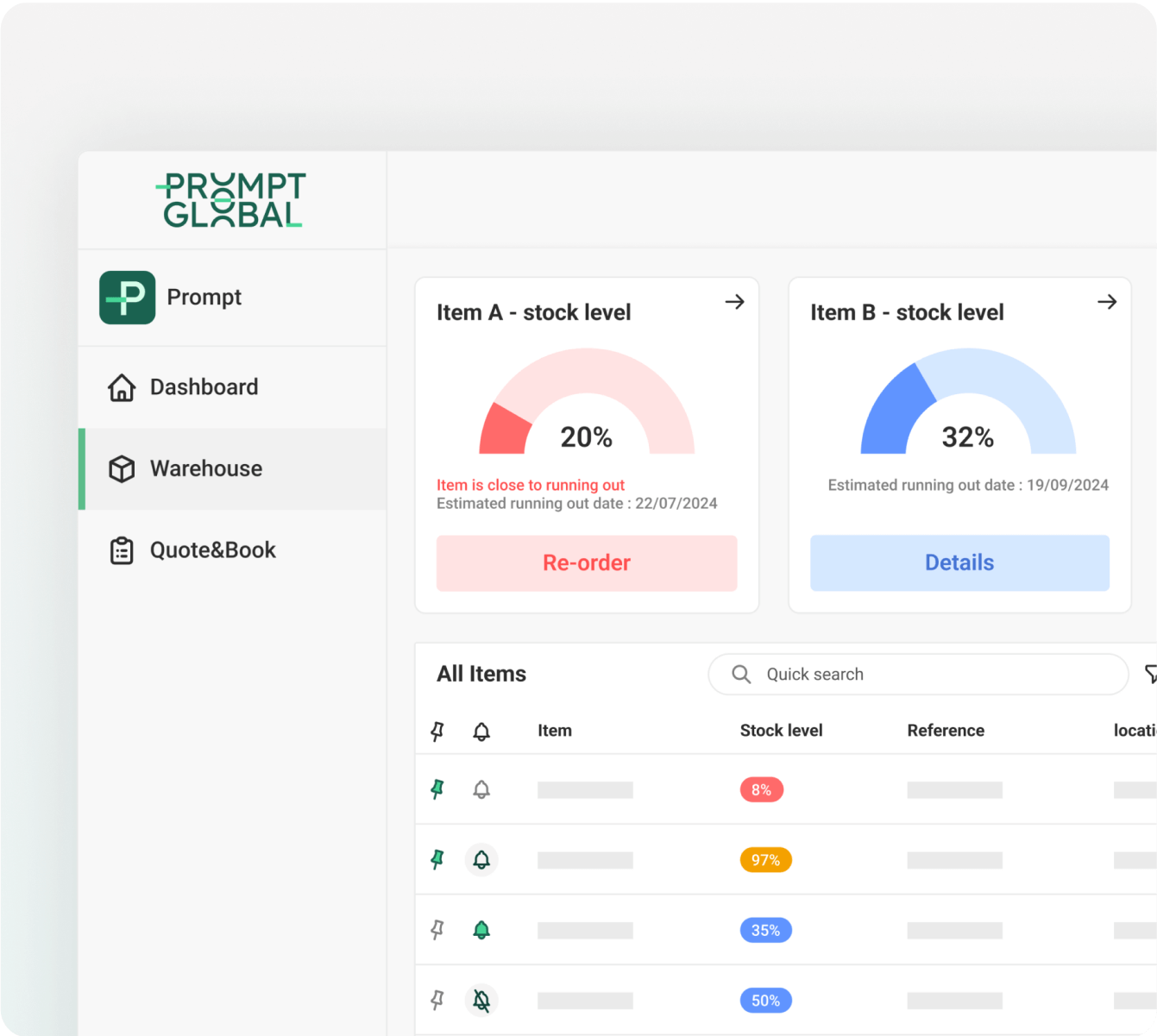

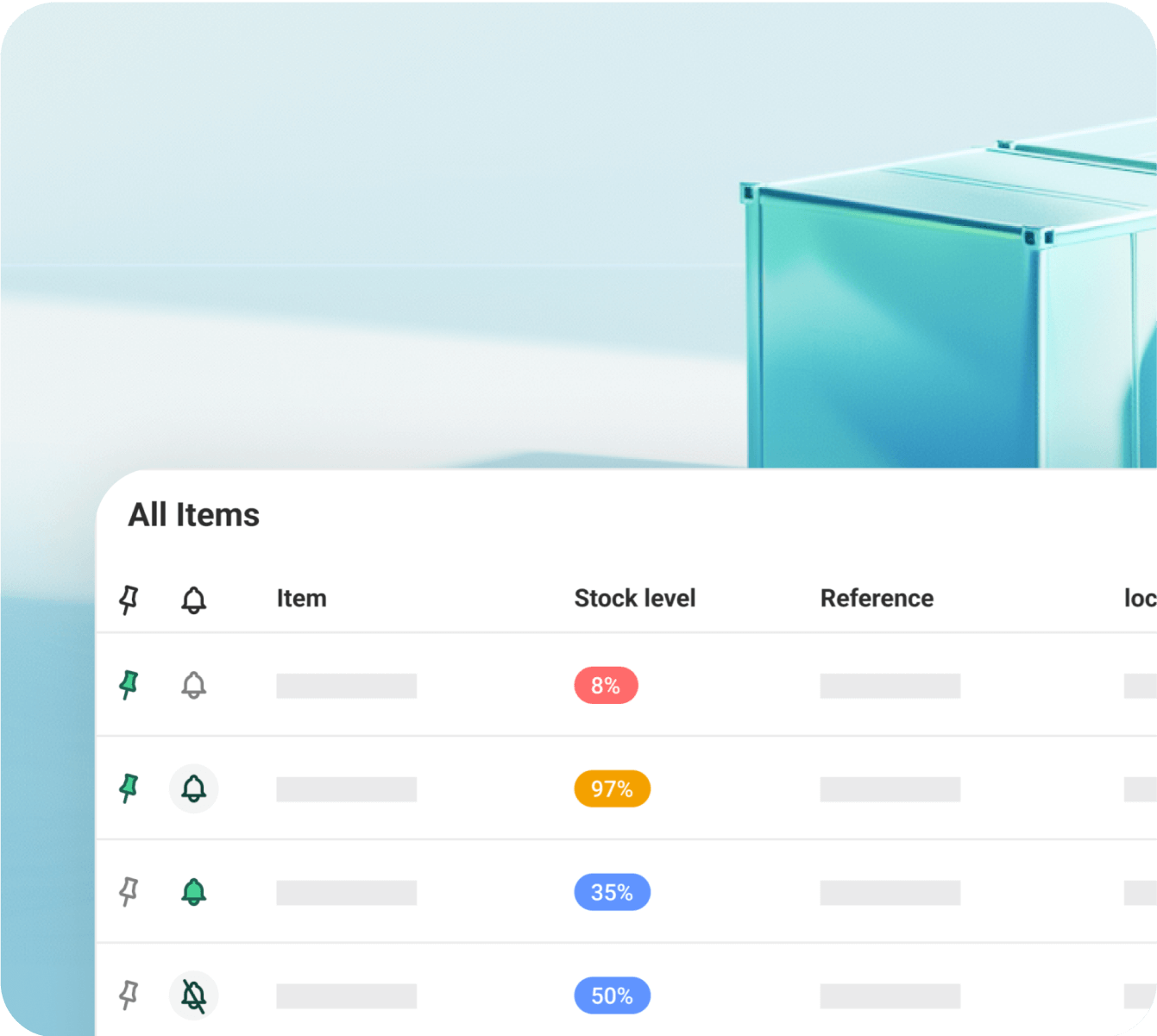

Make your data actionable using a fully customizable and configurable front-end, identifying the root causes of exceptions and unexpected fluctuations in stock levels such as late suppliers, carrier service level failings, bad performing routes, and more.